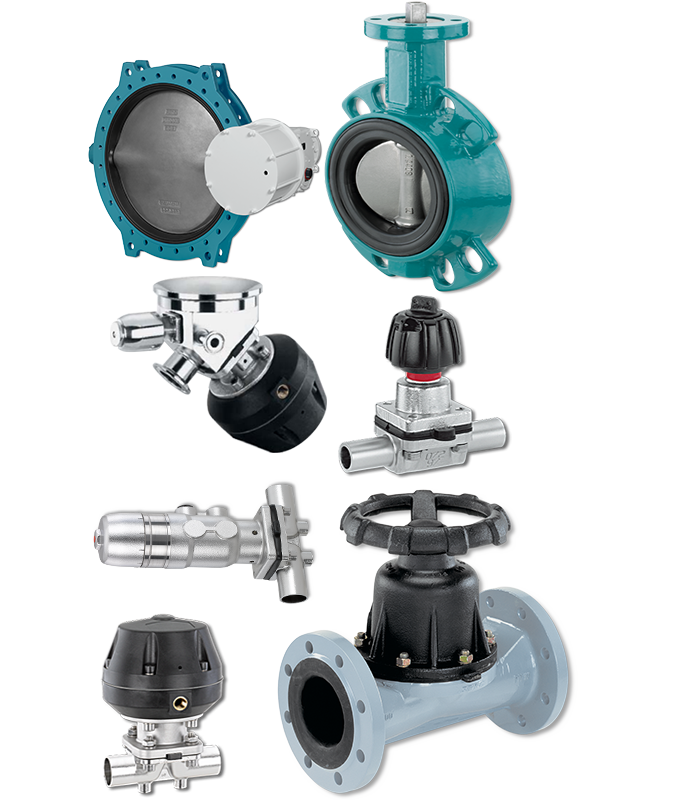

GEMÜ Valves

- Home

- GEMÜ Valves

GEMÜ – is a manufacturer of innovative and high-quality valve technology, with world-class facilities in Germany, Switzerland, China, and Brazil and over 2000 employees worldwide. Most of GEMÜ´s solutions are available in metal or plastic materials.

Products;

Mining Industry – All minerals: Diaphragm valves, globe valves, ball valves, and butterfly valves in plastic.

Food and Beverage Industries: Aseptic diaphragm valves, Globe and control valves, Automation components

Chemical Industry and Environmental Systems: Diaphragm valves, globe valves, ball valves, butterfly valves in plastic, and Lined diaphragm valves.

Water Treatment: Butterfly valves in metal and Plastic, Globe and control valves in metal and plastic, Check valves, Gate valves, knife gate valves, Ball check valves

Processing Industry: Globe and control valves, Butterfly valves, Ball valves, Solenoid valves

Power Generation: Butterfly valves in metal and plastic, Ball valves in metal and plastic, Plastic diaphragm valves, and Lined diaphragm valves

Pharmaceutical, Biotechnology, and Cosmetic Industries: Aseptic stainless steel diaphragm valves, 2/2-way and T body valves, tank valves, tandem welded configurations.